Structural reinforcements and Stratification

Structural reinforcements

We can increase the mechanical resistance of our prototypes by means of two techniques: Stratification of technical fabrics and metallic galvanic deposition.

They differ in the technical approach of preparing the prototype on which to carry out the reinforcement, in the times and in the result; it is best to agree on the technology to be used before starting production.

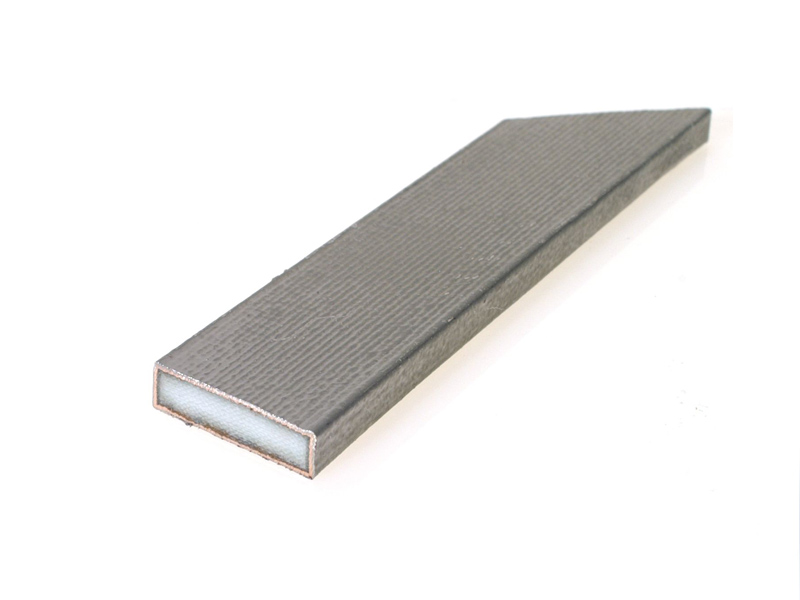

Stratification of technical fabrics

Stratification is carried out manually in the areas where greater resistance is required.

Depending on the application we can use glass, carbon and kevlar fabrics, impregnated with epoxy resins also resistant to high temperatures.

In the layering phase, if the geometry of the prototype allows it, it is possible to drown further reinforcements (for example metal plates, screws, or wooden boards).

Note that the reinforcement layering is not aesthetic.

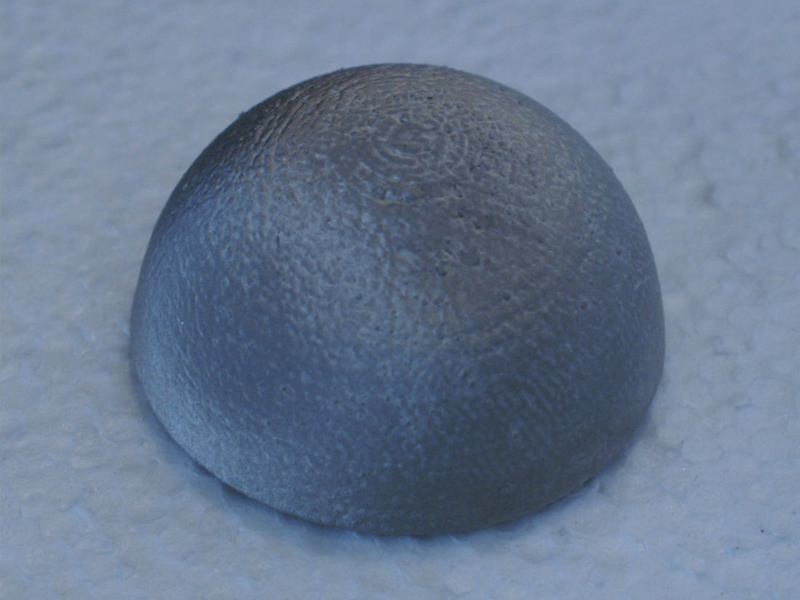

Galvanic Deposition

In cases where extraordinary mechanical resistance is required, we can coat our prototypes with Copper and Nickel by means of a galvanic bath.

The coating is consistent (from 0.1mm up to a few mm of material) and definitively solves any problem of mechanical, thermal and electrical conductivity.

of the plastic materials with which the prototypes are produced.

The process is also applicable to complex geometries, with the limits imposed by galvanic technology: tip effect, galvanic shielding etc.

Note that the coating is not aesthetic; the parts coated with copper only are painted with transparent to prevent oxidation.

Workable dimensions: up to 1900 x 2400 mm