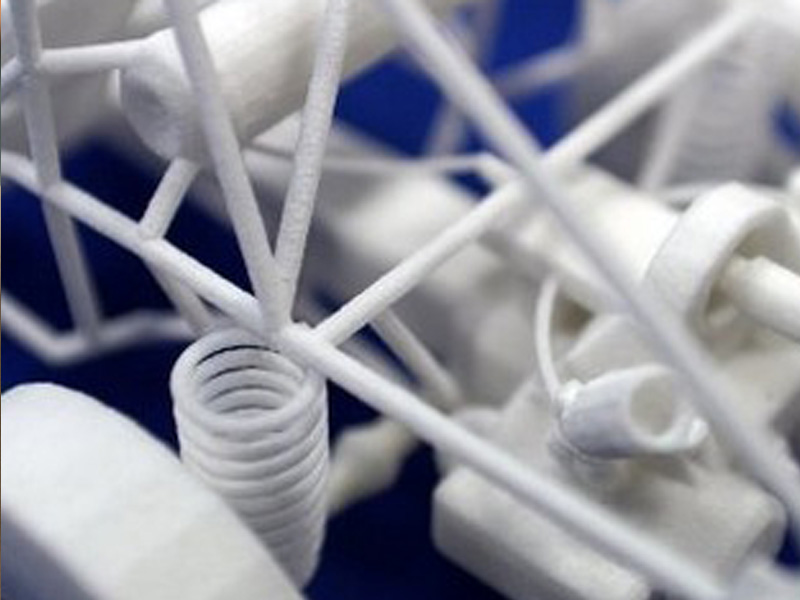

SLS Sintered 3D Printing

Laser sintering allows, starting from a 3D file, to economically and in a few hours produce Nylon models of even complex shape, difficult to obtain or even impossible with other means.

The models obtained are usually used for style verification, assembly tests, functional tests such as mechanical and thermal stresses.

OVER 1000x1000x1000mm for assembled prototypes thanks to the use of special adhesives, gluing techniques and joining systems, for which we are able to guarantee the mechanical seal of the finished piece.

All sintered products are finished to obtain a high level of quality also from an aesthetic point of view.

Assembly verification service is already included in the case of assemblies, and all aesthetic surface treatments are applicable.

Dimensional tolerances: ± 0.2% ± 0.2mm

Minimum wall thickness: 0.5 mm

Production times: on average 12h – 3 days from order and arrival of the 3D files that can be produced (variable according to the dimensions and specific requests).

Disponibilità macchina e materiali:

Vanguard HS+HiQ Volume di Costruzione 380 x 330 x 450 mm

Materiale

Nylon PA (Poliammide)

Nylon PA con carica alluminio

Elastomero Duraform Flex (65 ShA)